Last updated on: January 10, 2025

Table of Contents

- Introduction of MEP Coordination

- Building Design Phases

- Approaches for Design Coordination of a Construction Project

- About Building Design Systems

- What is MEP Coordination?

- BIM – An Integral Part of MEP Coordination Process

- How to do MEP Coordination in BIM-based Design?

- Benefits of MEP Coordination using BIM

Introduction of MEP Coordination

If your building design philosophy is ‘First Time Right’ and you firmly believe in ‘Prevention is Better Than Cure’ than you will truly appreciate the value that BIM-based MEP coordination (also known as design collaboration) process brings to a design and construction project.

In this article, our goal is to walk you through the entire MEP coordination and share a Downloadable Checklist (Design Coordination & Drawing Review) and Downloadable Infographics (Construction Coordination Workflow & VDC/BIM Coordination Dashboard) that you can use it for your current or upcoming design and construction project.

Before we get into MEP coordination, let us understand design phases, building-design approach, and building services.

No worries. Let us send you a copy so you can read it when it’s convenient for you. Just let us know where to send it.

Building Design Phases

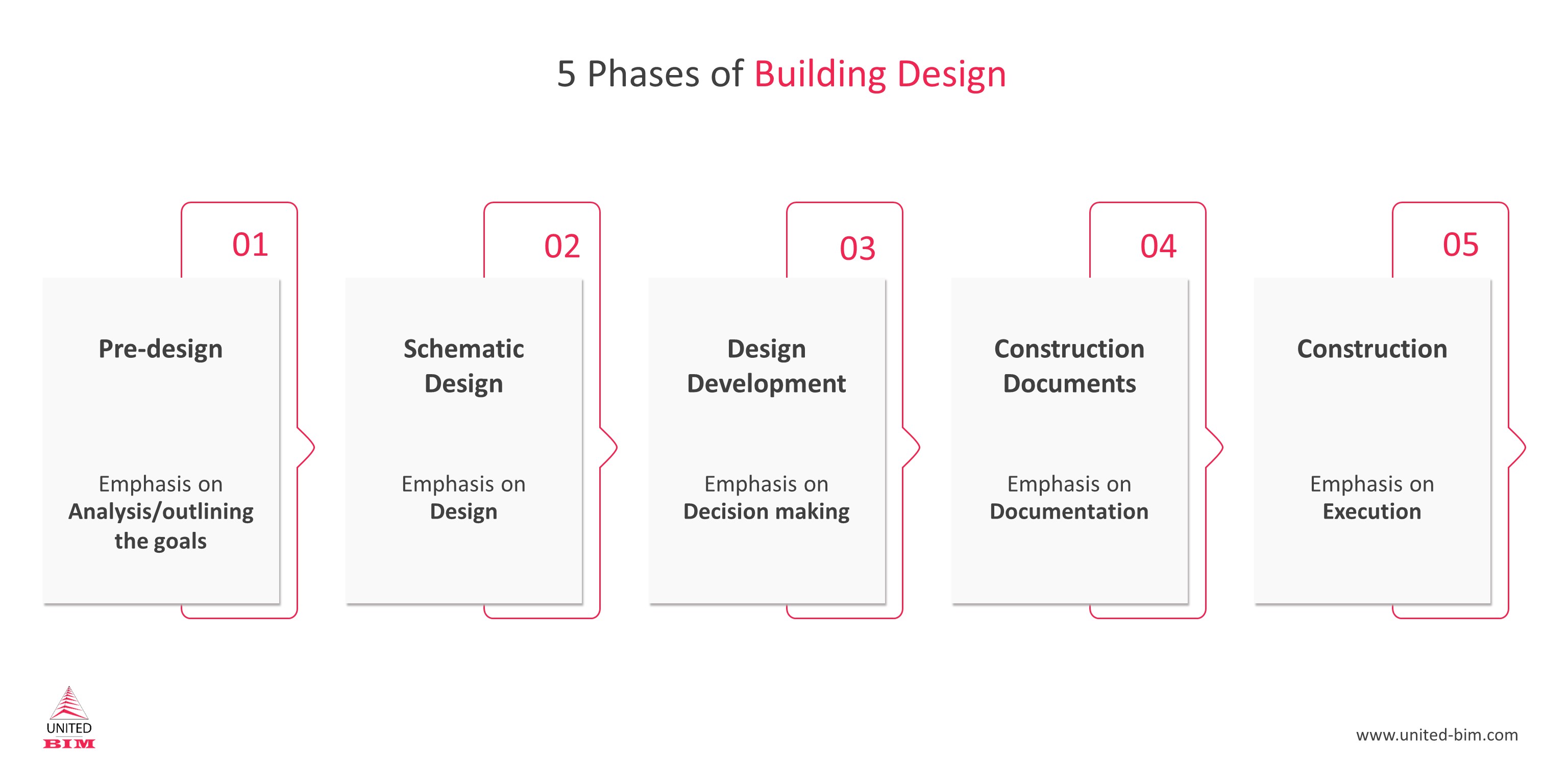

American Institute of Architects, Pittsburgh in their community article has separated the building design process into multiple phases. We have outlined five phases and included the emphasis of each phase.

Approaches for Design Coordination of a Construction Project

Traditional approach

For many centuries the basis of architecture projects were 2D drawings (plans, sections, elevations) and in those designs, it was hard to find out the interference.

Traditionally MEP coordination is conducted through a “sequential comparison overlay process” (Riley et al. 2005; Khanzode et al. 2008; Korman and Speidel 2010). In this process, the functional design is prepared by a consultant engineer, while the detailed design for each trade is developed by specialty contractors. The specialty contractors sequentially compare their shop drawings of the same scale on a light table and try to identify potential conflicts. Obviously, this manual method is costly, time-consuming and inefficient.

When CAD was introduced, designs were made in a 2D model, in this method there is no automated system to identify the clashes/conflicts in the MEP system and therefore there is a high degree of reliance on the intuition, imagination, technical knowledge and experience of the team members to put out the services without site teams experiencing clashes.

2D drawings can show the layout of it but can’t detect the conflict or the clash since that’s only possible with 3D simulation/model and also there is always a challenge of getting required (requested) MEP space from the design team members.

Image Credit: https://www.instructables.com/id/light-box/

BIM-based approach

BIM-based (3D modeling) approach modernized the design process by providing a virtual 3D model of the building which can be developed before the actual construction begins. This virtual model provides/delivers speed as well as convenience, making design changes in a 3D model is easier. You can easily alter any part of a 3D model, eliminating the need to redraw the design again and again. Also, the 3D model shows the clashes/conflicts between different trades/disciplines.

The BIM-based approach during MEP coordination facilitates collaboration among all the different discipline specialists (includes Mechanical, Electrical, Plumbing, Structural engineers), so that they could share comparative data and necessary interdisciplinary information with each other. BIM allows for simplification of many tasks and considerable savings both in terms of money and time.

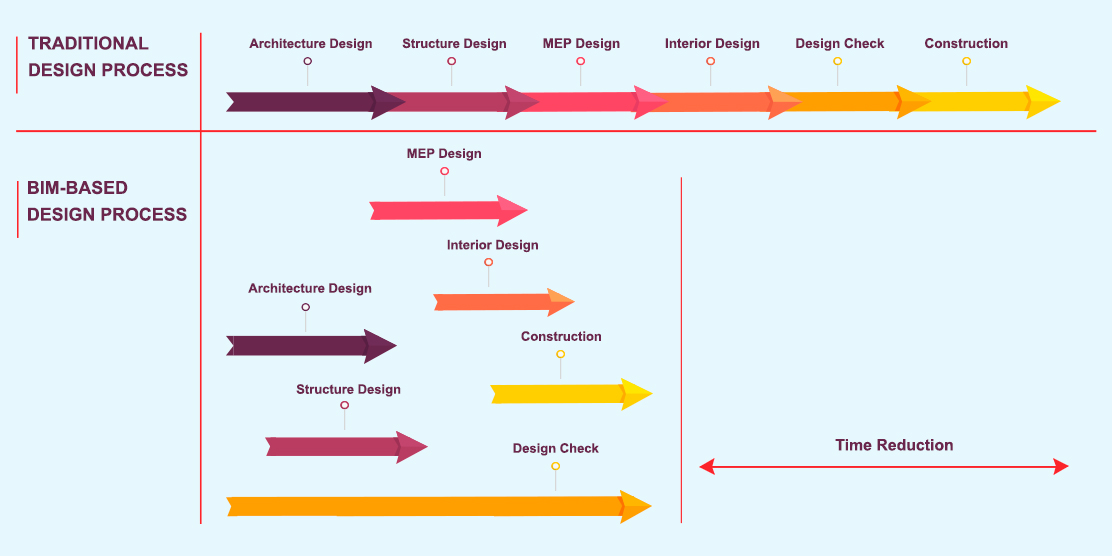

With respect to MEP coordination, the traditional design process relies on the completed design from all project participants (trades/discipline), while in the BIM-based approach it starts in the earliest form of design development process stage.

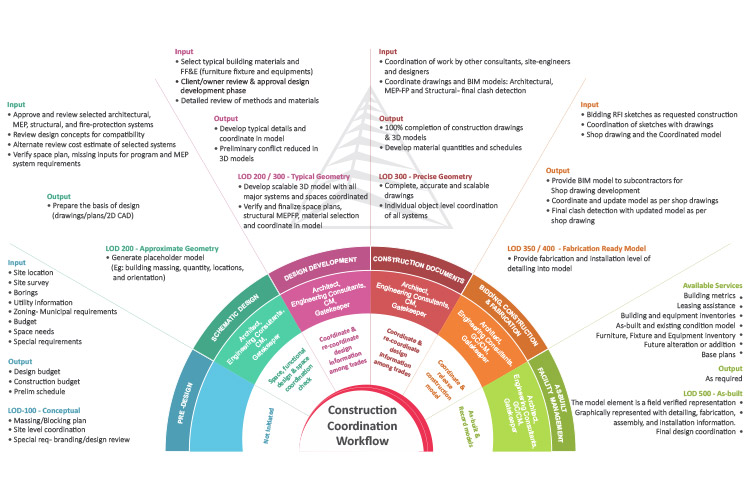

Usually, MEP BIM models are developed at five level-of-details:

- 3D MEP preliminary design model (LOD 100)

- 3D MEP detailed design model (LOD 200)

- 3D MEP construction design model (LOD 300)

- MEP construction model (LOD 350)

- MEP prefabrication model (LOD 400)

Looking for Clash Detection and Coordination Services for Your Design and Construction project. Contact us with your requirements.

The following image shows differences between the traditional design coordination and the BIM-based design approach.

All designs start with sketches and move to 2D drawings (Autodesk’s AutoCAD widely used) and then advances towards the 3D model (Autodesk’s Revit widely used) in the case of the BIM-based design approach.

Revit follows a BIM (Building Information Model) workflow as compared to a CAD workflow. With Revit, you can streamline the design documentation process and maximize productivity.

Downloadable Checklist (Design Coordination & Drawing Review) and Downloadable Infographics (MEP Coordination Workflow,) which you can use it for your current or upcoming design and construction project.

Now let’s understand building service systems and how important they are for MEP coordination/collaboration:

About Building Design Systems

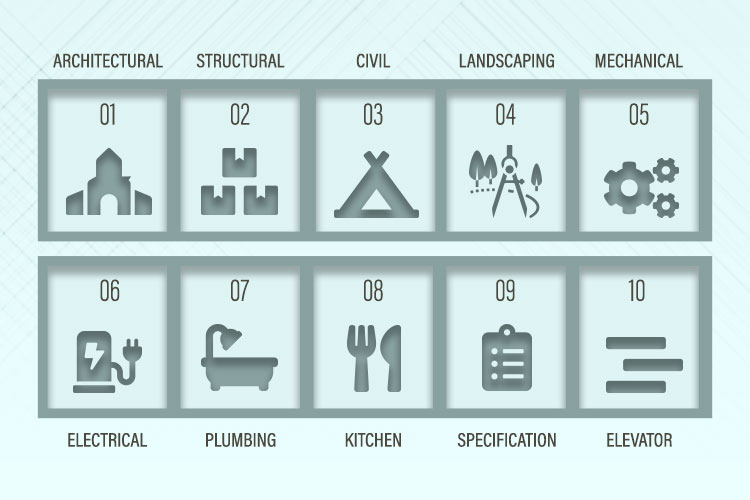

As per Bachman 2004, the fundamental building systems classifications are:

- Architectural system – Indoor and outdoor separation: wall, fenestration, roofs

- Structural system – Elements providing static equilibrium against gravity and dynamic loads

- Building services – HVAC, electrical, plumbing, vertical transportation, and life safety systems

- Interior systems – Occupied space encompassing partitions, finishes, lighting, acoustics, and furniture

- Site service – Landscape and support systems for the building, including parking, drainage, vegetation, and utilities

Building service systems termed as the active building systems include mechanical, electrical, and plumbing (MEP) systems. Building services must fit within the constraints of architecture and structure and must meet the expected performance regarding comfort and safety. Building systems moderate the building environments, distribute electric energy, allow communication, enable critical manufacturing process, provide water and dispose of waste, and provide critical resources for life safety as mentioned in Korman 2008.

The scope of building services systems is continually increasing due to increasing requirements for building users. Building projects now include more than the traditional Mechanical, Electrical, and Plumbing systems, such inclusion is fire protections, controls, process piping, and telephone/datacom as per Korman 2008.

Get a Quote for Virtual Design and Construction Services

What is MEP Coordination?

MEPFS coordination is a practice of multi-disciplinary collaboration of three major design verticals of any building infrastructure, which are architecture, structure (beam, column, torsion, etc.) and MEP designs.

The active systems of the building namely Mechanical, Electrical, Plumbing (MEP) and Fire Safety (FS) frameworks are fundamental components of any building, they have been estimated to cost up to 60% of the total cost of the building projects as per Korman and Huey-King 2013. Mechanical, Electrical, and Plumbing (MEP) coordination is one critical activity and an important part of the constructability review process. Three knowledge domains are required for MEP coordination, namely, design, construction, and operations and maintenance.

The trades of MEPFS Coordination are:

- Mechanical System – HVAC Equipment and distribution such as Cooling tower, AHU, Ducting, etc.

- Electrical System – Panels, switchboards, elevators, transformer, cable trays, etc.

- Plumbing and Sanitary System – Pumps, water holding tanks, pool filtration equipment, Sump, sewage pit, grease and sand traps, etc.

- Fire Safety System – Fire sprinkler pumps, sprinkler tanks fire shutter, smoke curtains, piping system, etc.

- Outside of Building – External works, rooftop, and external face of a building, etc.

MEP coordination is all about detecting and resolving clashes among trades – architectural, structural, mechanical, electrical, plumbing and fire safety before construction starts.

To keep the harmony between these separate designs, it’s essential to have a coordination of updated designs of each discipline. Each discipline must be precisely aware of the locations of other installations during the modeling phases and this can only happen when the latest, most precise version of each MEP’s master plan is made available. It may happen that these designs have collisions or clash in some locations, where one or many components are occupying the same space. It is very crucial to get knowledge of these clashes at an earlier stage of the construction project which can cost you millions if not detected in the design phase.

MEP coordination service is about synchronizing all the building services with other disciplines that form the building fabric, structure and external envelope (steel, concrete, etc.). Building service coordination involves assigning horizontal and vertical locations for individual systems components within the defined architectural and structural constraints. Mostly the professionals conducting the coordination process focus on highly congested spaces within the structural systems to prevent building service systems interference.

The building services coordination at the design development and review stage is the first stage of coordination of building projects.

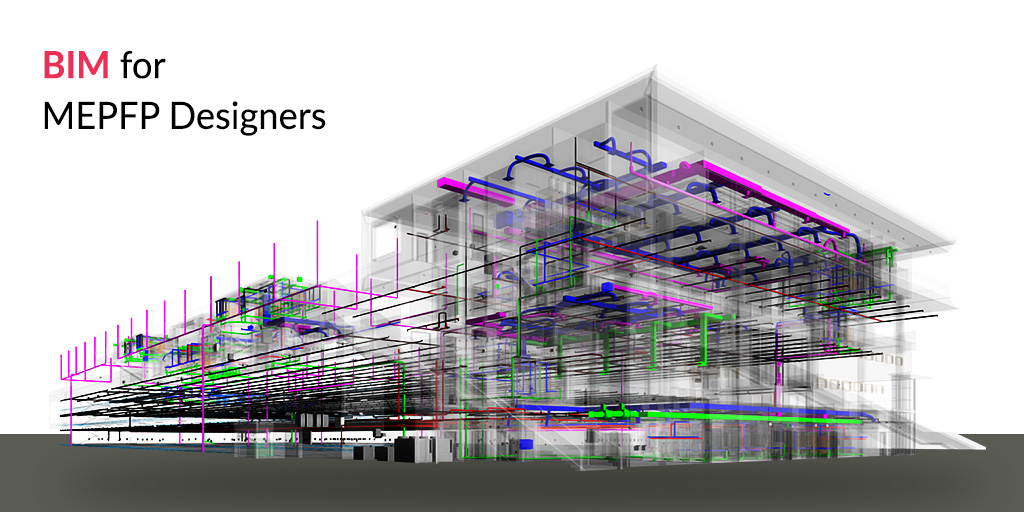

BIM - An Integral Part of MEP Coordination Process

BIM gives a visual capacity (through 3D modeling) to the structures and intently speaks to the developed structure at the pre-construction stage. This technology-based approach for coordination offers multiple advantages as communication and collaboration begin at the 3D modeling stage itself. MEP BIM 3D Modeling services comes in the later stage after the Architectural BIM and Structural BIM models have structured the premise for an MEP BIM model.

Fundamentally, BIM not just resolves the structure coordination and modeling difficulties however it helps coordination between different teams, contractors, fabricators, consultants and engineers to build up a consistent communication channel. It goes above and beyond and works together with new advances to encourage better task results.

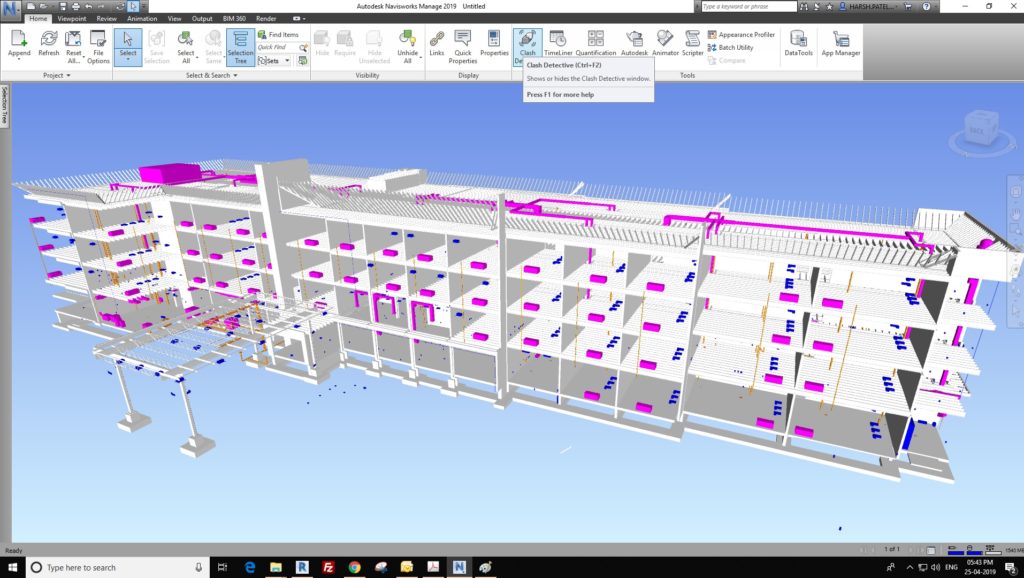

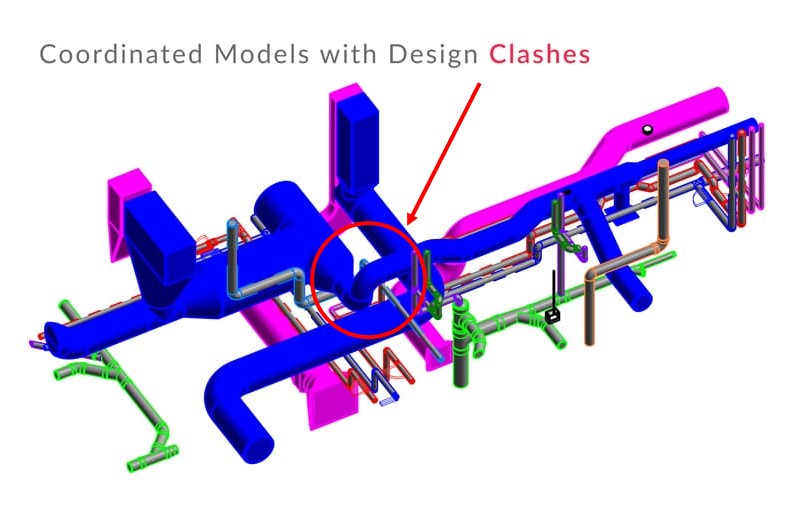

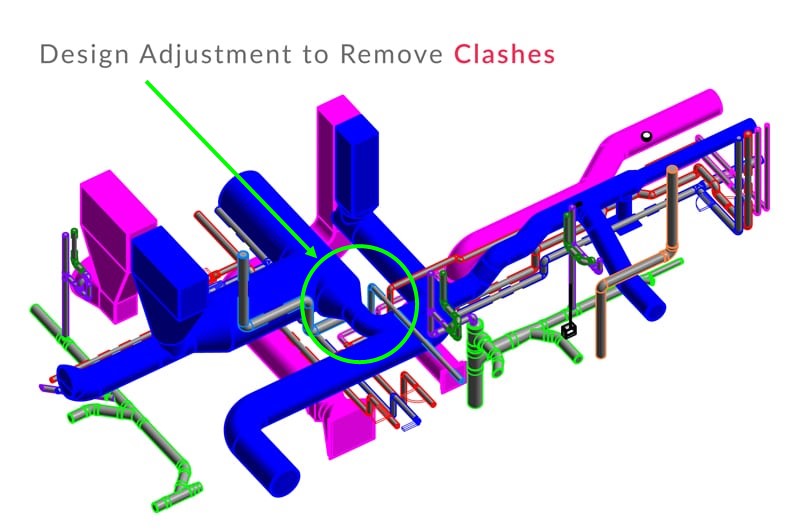

In the BIM-based approach, MEPFS 3D coordination modeling (Autodesk’s Navisworks widely used), highlights all clashes within MEP systems against other MEP systems or MEP systems against structural) integrates each team’s designs and finds out all the clashes, ensuring that there is harmony between the Architectural design, Structural design, and MEPFS design. Conflicts eliminated at an early stage will surely have a positive outcome on the project.

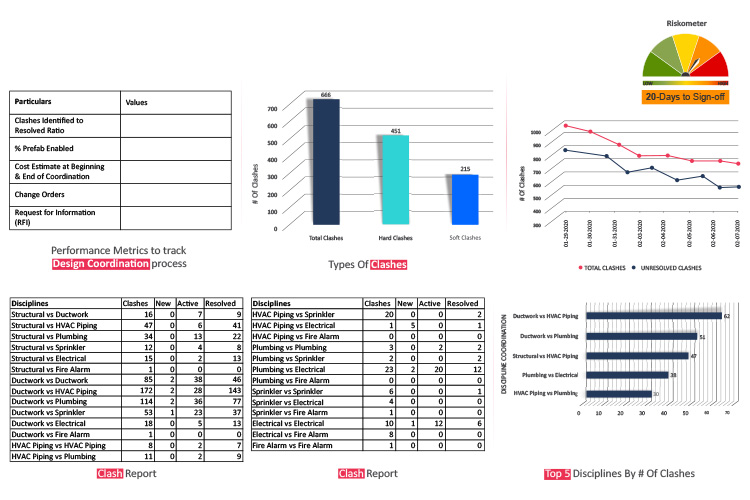

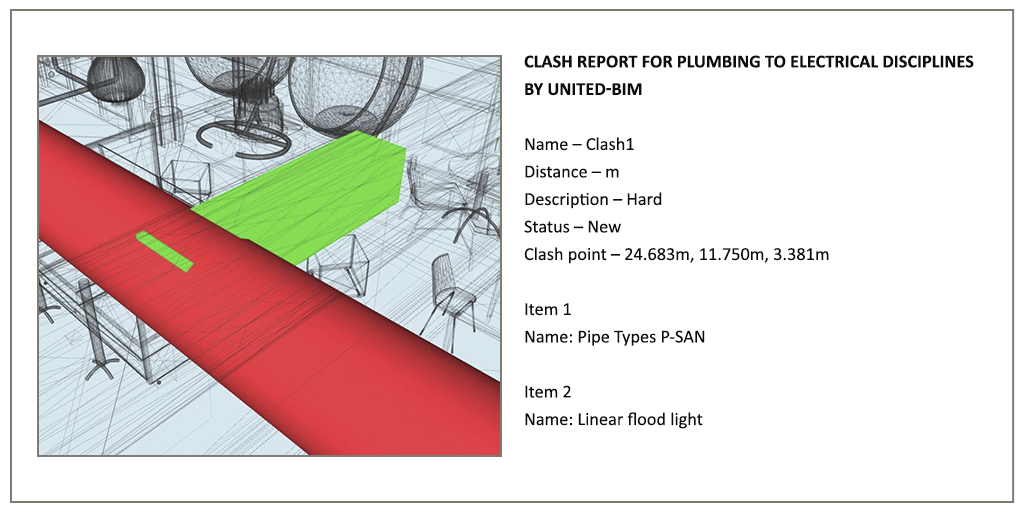

At this stage, MEP coordination services provider like United-BIM can help you in MEP Coordination. Once we run the clash detection process in Navisworks by providing Architectural, Structural, and MEP models, we have the clash report showing possible collisions or clashes at multiple locations with reference positions in the coordinated design. After locating and analyzing the cause of clash, the required design changes need to be done to solve the clash.

A BIM representation can be viewed as a smart object or parametric model that changes in all views if any one input is updated since it is all digital.

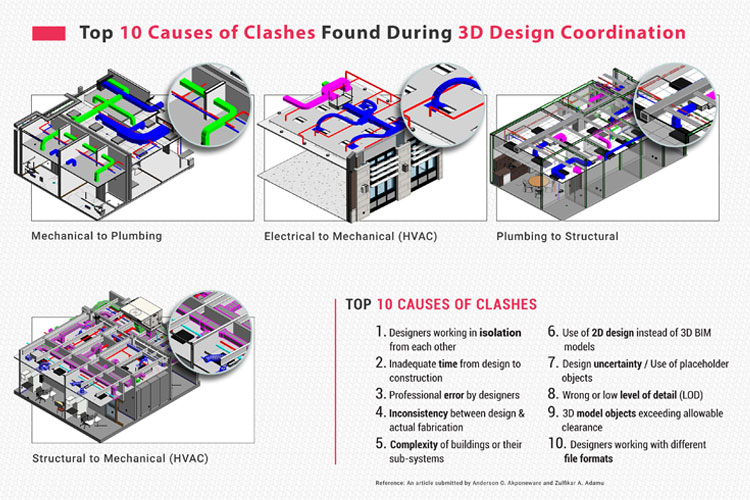

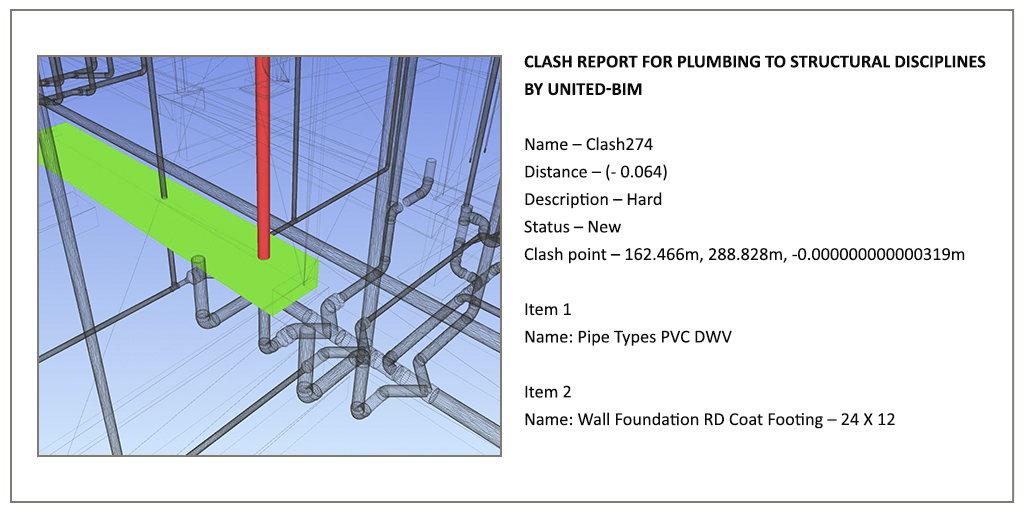

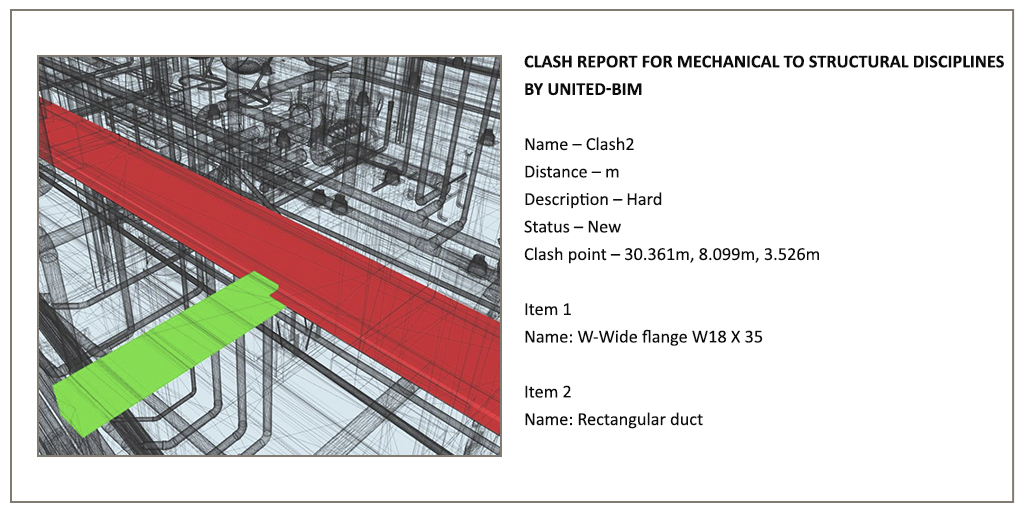

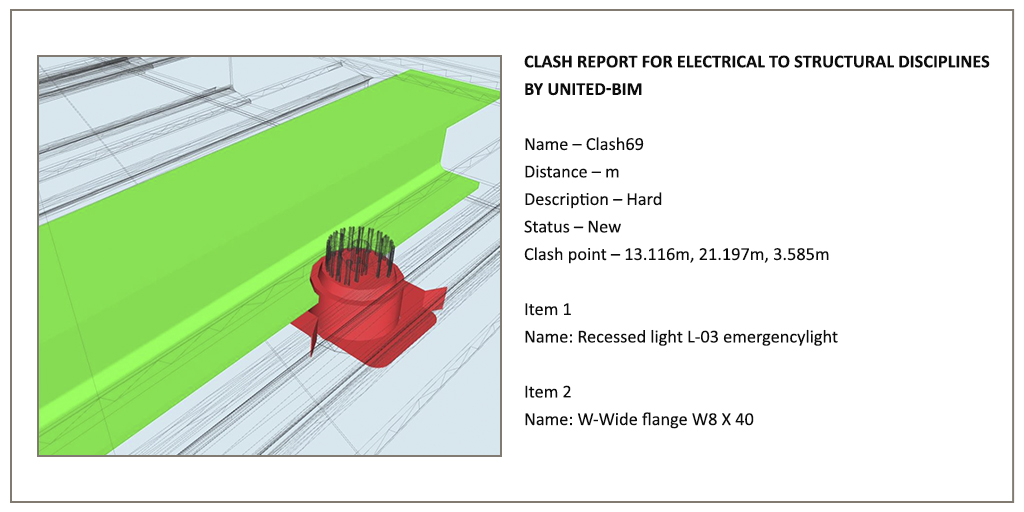

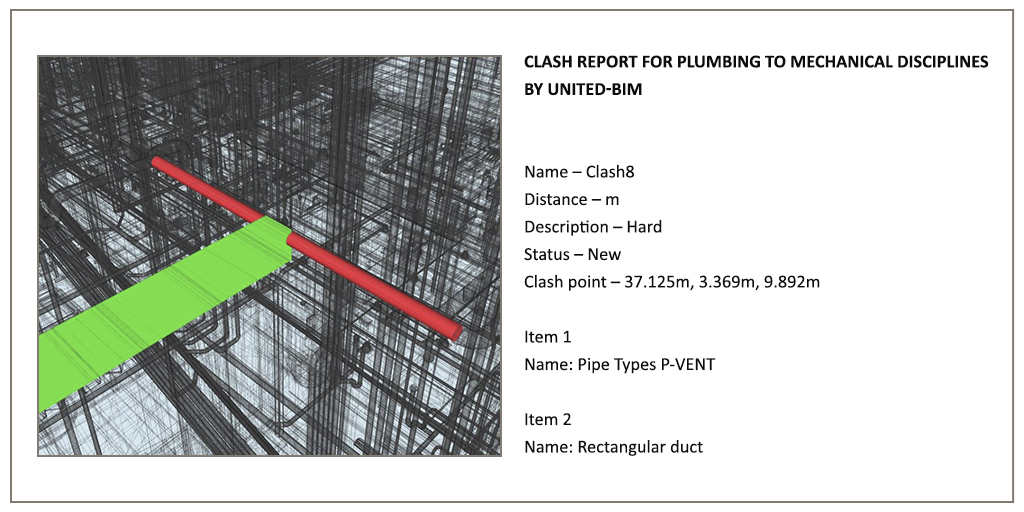

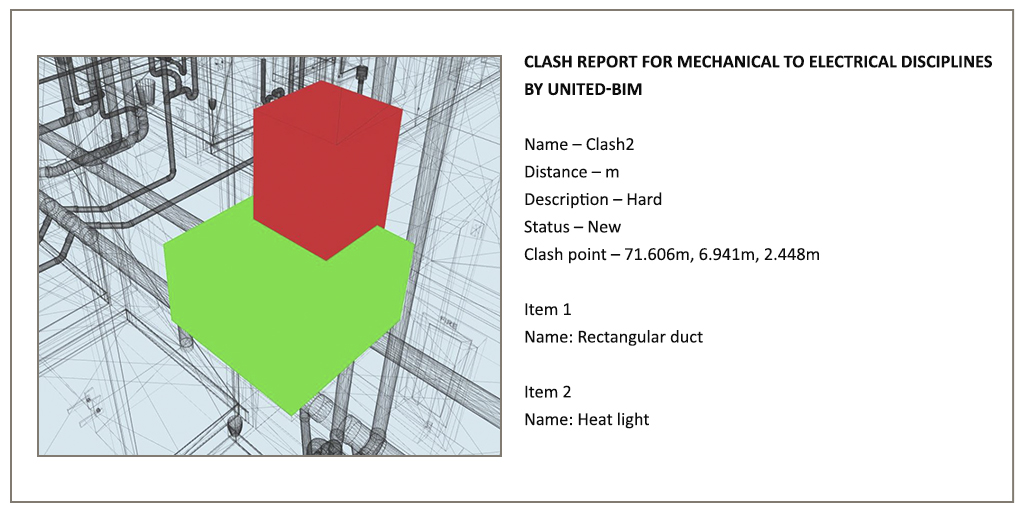

As per our experience of over 300 projects, most clashes are found in “Plumbing to Structural” and “Mechanical to Structural”. Here is a list of coordination of different disciplines with the examples of their clash report.

1. Plumbing to Structural (mostly found with flange and foundation)

2. Mechanical to Structural (with Flange)

3. Electrical to Structural

4. Plumbing to Mechanical

5. Mechanical to Electrical

6. Plumbing to Electrical

Here are the images showing clash (plumbing and HVAC duct) and how easy it is to resolve the clash in a 3D BIM model.

How to do MEP Coordination in BIM-based Design?

MEP coordination starts in Schematic Design (SD) phase and it has to be completed before the Construction Documents (CD) phase. Usually, GC (General Contractor) holds a Gatekeeper meeting where all disciplines are involved and collectively they review clash reports with an objective to have a design that is completely clash-free.

Download a template of MEP Dashboard for Gatekeeper Meeting. It is specially designed for you to track down the MEP coordination and clash detection activities from the start of the meeting till the final sign-off meeting.

Download an infographic of Top 10 Causes of Clashes Found During 3D Design Coordination.

Let’s look at the flow of how MEP coordination is carried out in the design and construction project.

There are 5 steps to successful MEP Design & Coordination process:

Step 1: Using Right MEP BIM Template

Load MEP BIM Template before the start of a new project. The template should be based on the company’s standards for each of the listed trades:

- Mechanical Services

- Electrical Services

- Plumbing and Sanitary Services

- Fire Protection Services

Step 2: Architectural Model Validation

Verify/Check the coordinate of the Architectural model. It is important to have the same coordinates for both MEP and Architectural models before linking them. The best approach is to use the “Origin to Origin” positioning option for placing both models.

Step 3: Prepare the MEP Model

Prepare MEP model each of the disciplines/trades – Mechanical (HVAC etc.), Electrical, Plumbing and include all elements before linking them for coordination with other sub-disciplines within the central file.

Coordination or collaboration between MEP sub-disciplines within the building are:

- Level by Level (Story by Story)

- Room by room (Below Raised Floor)

- Horizontal Space (Plenum)

- Vertical Space (Core Shafts)

And collaboration elements outside the building are:

- Mechanical System – HVAC equipment and distribution, ducting, etc.

- Plumbing and Sanitary System – Pumps, water holding tanks, pool filtration equipment, Sump, sewage pit, grease and sand traps, etc.

- Fire Protection System – Fire sprinkler pumps, sprinkler tanks fire shutter, smoke curtains, piping system, etc.

- Electrical System – Panels, switchboards, elevators, transformer, cable trays, etc.

Step 4: Run the Clash-detection

In Autodesk’s Navisworks any two disciplinary models are coordinated together and by clicking on “Run Test”, it shows the report of the clashes occurred between the coordinated model.

Step 5: Review and Resolve

In this step, we can know the ID of the element that clashes, and fix it in the Revit file.

Once all clashes/conflicts are solved in the Revit file, you have to export it again, with the same name and in the same folder. When you reload the cache in the Navisworks, resolved clashes will appear in the yellow in the “Resolved Section”. If any new clashes emerge, they are classified in red as new.

Get Clash Free and Coordinated Model for your Construction project. Contact us with your requirements.

How MEP Coordination can help in a Construction project?

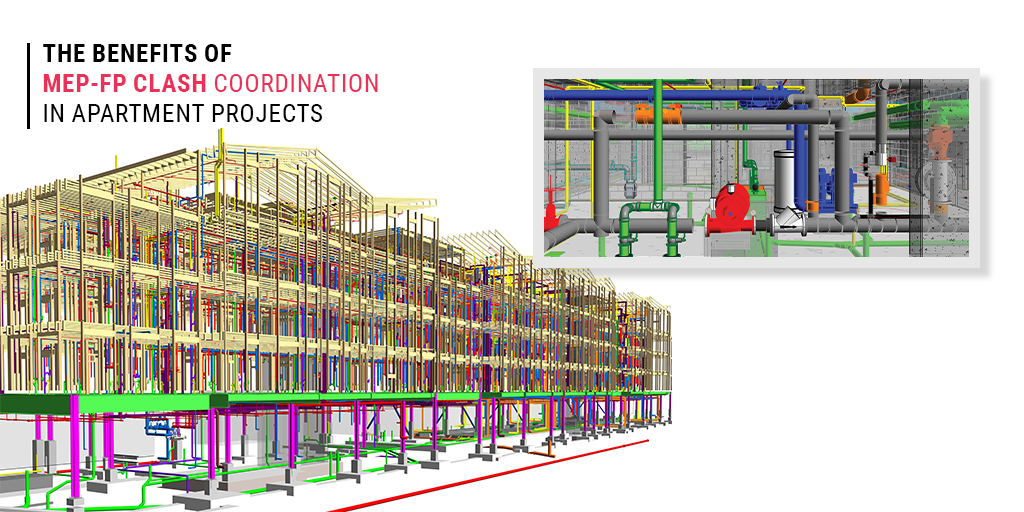

In some cases, around 40% of a building’s construction budget can go into project’s Mechanical (i.e. ducts, pipes, equipment, etc.), Electrical (i.e. light fixtures, data/power outlets, etc.), Plumbing and Fire Protection systems; huge monetary investment that has impact on operating cost of the building in both, shorter and longer run. Thus, to establish disciplined MEP coordination in a construction project is admirable for every sector. A well-executed MEP design coordination can save you millions and maybe more importantly deliver the project faster.

Through MEP coordination, when the clash is detected in design, the Architect & Engineer can collaborate and decide upon the redesign of collided design elements. The new version of the design is updated in the entire design model. This multi-disciplinary collaboration can save designers and engineers from cumbersome efforts of repetitively updating designs.

MEP Coordination is also useful for retrofit and redevelopment projects. There are technologies and software available to capture existing infrastructure with accuracy. HVAC, electrical, and plumbing model retrofit provides improvements in energy and building performance through MEP coordination. Reality computing and Point Cloud Scan to BIM are some of the technology which enables us to fully coordinate the MEP model of existing facilities in a quick time.

Greater flexibility, scalability, swifter turnarounds, a reduction in overhead expenditures, and access to state-of-the-art resources are all benefits of outsourcing BIM MEP coordination. Feel free to contact us with your project details, and we will be excited about providing BIM consulting.

Benefits of MEP Coordination

- Clash-free Design

- Reduce Project Rework

- Collaboration at Early Stage

- Cost Saving

- Reduction in Material Waste

Benefits of MEP Coordination using BIM

Let’s talk about benefits, it is a no-brainer and very well understood but still, it is important to highlight the key benefits and what advantages it offers to various stakeholders and to the project.

1. Clash-free Designs

A 3D model for Architecture, Structure, and MEP is made dependent on the plans created by the BIM modelers. This model is then sent out to Autodesk’s Navisworks where it is checked for the clashes and a clash report is created. These clashes are settled by making the vital structure changes in the BIM model. Since the clashes are effectively unmistakable in the model, it is simpler to determine them.

2. Reduce Project Rework

A lot of time and money can be wasted if the clashes are found at the construction stage (i.e. in the field) and then they need to be rectified. Having MEP BIM Modeling services can reduce the amount of project rework and limiting waste.

3. Collaboration at Early Stage

The professionals are required to work together at the designing stage and they will be able to explain their specifications to other team members. Because of the early collaboration, the design can be more effective and there will be fewer mistakes to be rectified at the time of construction.

4. Cost Saving

BIM can build a building twice, first as a model with all the data and second on the site. This guides in the goals of any contentions before the beginning of the actual construction. These changes are simpler and more affordable when contrasted with the changes that should be done on-site (i.e. in the field). This, thus, lessens wastage as far as material and labor, consequently saving money as well.

As per Riley (2000), the average cost of fixing a field conflict on an average project was found to range from $500-$3500 for minor rerouting, $2,000-$25,000 for major conflict and design change.

5. Reduction in Material Waste

Effective coordination during the design stage will reduce waste generated by errors and alterations during the construction stage because the clashes are solved at the design stage.

Summary

BIM-based design and construction approach (part of Virtual Design Construction) allows data-driven collaboration among architectural, structural and MEP from the outset, increases design confidence, and simplified phasing. And as a result, the design-to-construction workflow is significantly overhauled.

References:

In this article, we have taken references of published materials by various experts and researchers. We have credited them throughout the article to acknowledge their work.

For those who like to get into details, we recommend reading the following references.

- Korman, T., Simonian, L., & Speidel, E. (2008). Using Building Information Modeling to improve the mechanical, electrical, and plumbing coordination process for buildings. In Proceedings of the AEI 2008 Conference, Colorado, USA.

- A thesis by Babatunde Adewale on the topic “A framework for the process of effective coordination of building services during the design development and review stages.”

- Building an essential guide for MEP consultants by Building and Construction Authority.

- Integrated Buildings: The Systems Basis of Architecture by Leonard R Bachman.

- American Institute of Architect Pittsburgh in its community article has separated the building design process into multiple phases.

- MEP Coordination in Building and Industrial Project by C. Bob Tatum and Thomas Korman

About the Author

Nirav Shah is a seasoned marketing leader with over 20 years of global B2B experience across the high-tech, IT, and AEC industries. He specializes in project management, digital marketing, brand positioning, and sales enablement. Until March 2024, Nirav led marketing initiatives aimed at delivering client-centric solutions while driving operational excellence. Known for his disciplined execution and ability to build and motivate high-performing teams, Nirav is a lifelong learner, dedicated to continuous improvement.