Last updated on: February 28, 2025

Table of Contents

- Standard Industry Practice

- Why Does Concrete Rebar Reinforcement Require 3D BIM Modeling?

- Concrete Rebar Reinforcement Modeling Workflow

- Implementation of BIM for Concrete Rebar Reinforcement

- 5 Tips for Effective Implementation

- 4. Quality Control View

- Cost & Benefit Analysis of Reinforced Concrete Rebar Modeling

- References

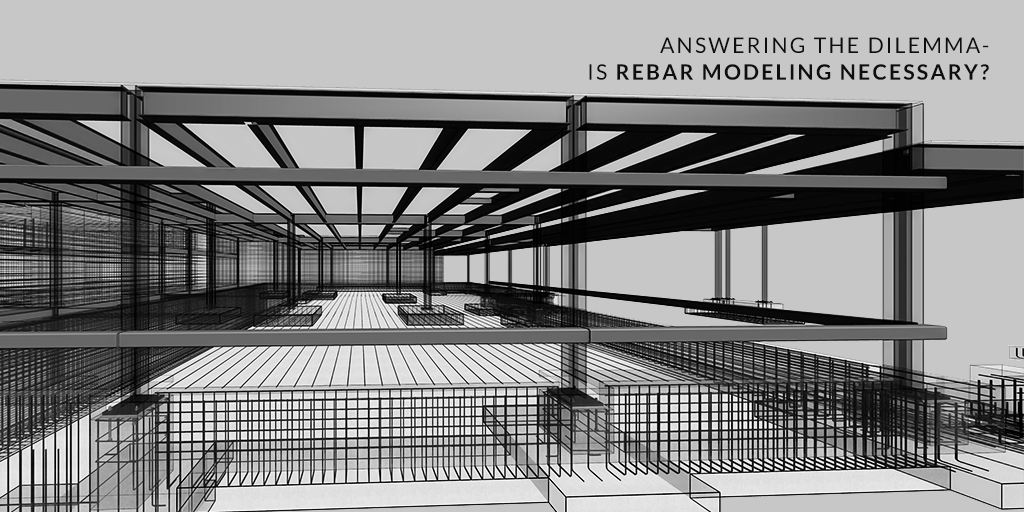

There is a common dilemma prevailing, I.e., “Why do we have to model all the rebars?” Modeling Rebar requires precision and an intricate level of modeling. Hence, it is often perceived as a time-consuming process.

This blog attempts to compare the 2D detailing process and the 3D modeling approach, wherein we highlight how we use Revit software for Rebar BIM Modeling and how it can become a powerful tool for designing and constructability of Concrete Rebar Reinforcement.

Standard Industry Practice

In the AEC fraternity, the standard practice is driven by contractual requirements. For every commencement of the project, specific guidelines for 3D BIM modeling are set with the required software. These guidelines include 3D model design reviews to ensure the status and the quality of the deliverables, manage the inter-disciplinary clashes, and support efficient and timely production of deliverables.

Know the Best Practices: What are BIM Dimensions – 3D, 4D, 5D, 6D, and 7D BIM Explained | Definition & Benefits

Why Does Concrete Rebar Reinforcement Require 3D BIM Modeling?

- Cross Disciplinary Environment– BIM allows the involvement of more than one discipline involved in the project. It is capable to combine Architecture, MEP, and structural design in one model.

- One model for all– When we model the structural design, we only need one model to perform multi-disciplinary coordination and for structural detailing.

- Customizable– BIM model is customizable and accessible for all the project teams.

- Features of Revit– Revit is one of the best software for reinforced concrete modeling and detailing. It has tools and features to perform structural rebar detailing that is straight out of the box.

Along with the pros of rebar detailing and modeling, there are few challenges:

- 3D reinforcement workflow to be adapted with the peculiarities of each project.

- Complex Concrete forms and designs are not handled always correctly.

Would you like to share your Project Details? We would be glad to discuss it with you! Click here to send us an E-mail now!

You can also call us at – (860) 317-7105

Don’t have the time to read the whole blog, no worries you can download it and read it at your convenient time.

Concrete Rebar Reinforcement Modeling Workflow

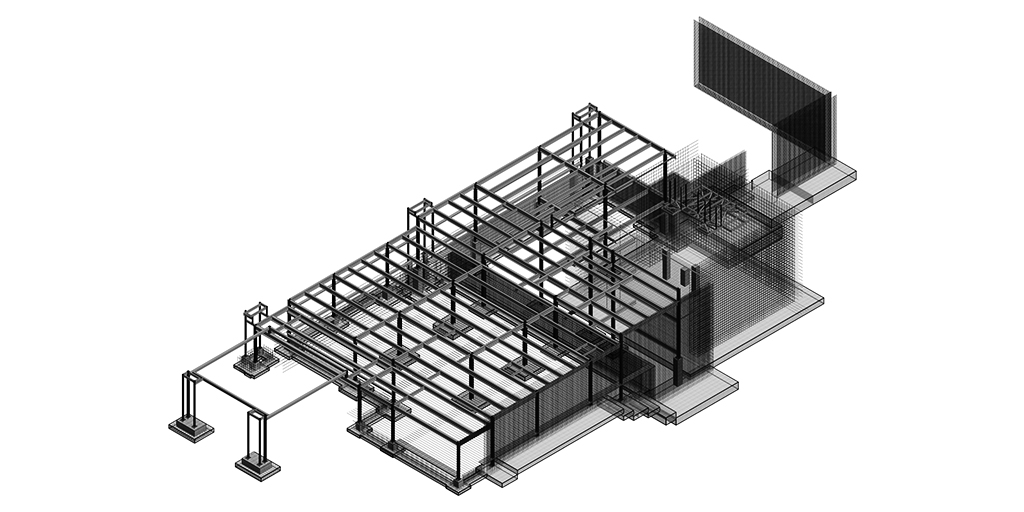

The accuracy of the concrete rebar reinforcement depends on the accuracy of modeling. Hence it is very important to create a standard quality workflow that enhances the collaboration between structural engineer’s design and BIM Modeler. The desired workflow involves three major steps:

- Creating 3D Geometry and the analytical base

- Exporting the model to the structural engineer for optimization and calculation of the loads

- Updating the BIM model with the loads

Before BIM Introduction:

Before BIM was introduced, structural engineers would create an analytical model using STAAD (Structural Analysis And Design Software). The design was done using Excel spreadsheets and this would result in the required reinforcement area. The sketches were then developed and given to the draftsmen. The symbolic presentation of the real rebar was done on AutoCAD.

The biggest challenge was the communication as there was no room for communication between the engineer and the draftsman. Secondly, there would be inaccuracies between the calculations, bending schedules, and drawings. And lastly, the engineer could only check the drawing once the final design drawing was created.

After BIM Introduction:

With the introduction of BIM, the reinforced concrete modeling is done on BIM authorized software, such as Revit. BIM has enhanced the collaboration of the engineer and the draftsman as they both can work on a centralized located file and can be regularly updated with the changes in the model. The analytical model prepared by the engineer can be exported in SAP200 software for validation. With the 3D BIM model in place, structural engineers can develop coherent Bar Bending Schedules & Bills of Materials.

Tap into More Information : 3D CAD, BIM & VDC | Difference, Scopes and Applications

The drawings are now more accurate with a stronger design and capability to evaluate the constructability of the project before actually going to the site. The increase in productivity raises and the quantity estimation and management issues decrease with this. The aim is to achieve perfect collaboration between the structural engineer and the BIM modeler.

Implementation of BIM for Concrete Rebar Reinforcement

To initiate the implementation, it is advisable not to start before having a small group of specialists. This step will include analyzing the need of the company. In the beginning, the aim will be to analyze the peculiarities to understand and develop possible BIM solutions to speed the process of rebar detailing, concrete reinforcement, etc. This step is required as this will be the base for all future modeling activities. If set correctly, rebar detailing or rebar modeling can become the strength and result in saving a lot go time, money, and resources than a traditional 2D reinforced concrete workflow.

This step includes developing specifically customized templates for each type of document that is required. For example, General Modeling, AADA Foundation, Pile, Pile Plan Detailing, Foundation Plan Detailing, Anchor Bolt Layout Detailing, Reinforcement Slab Detailing, Isometric Foundation Detailing, Geotechnical Section, etc. To get the best possible modeling speed, set up the required filter and different section types, like, Air Terminals, Analytical Beams, Braces, Columns, Floors, etc. With the correct template, filters, and types it becomes easier to create the reinforced concrete documentation required for structures of the building. The goal is to create all the drawings needed from one single model without dealing with detailed elements that are not belonging to the correct sheet or elements that are changing from one phase to another phase of the design progress.

Training is the most crucial step in the entire process of establishing BIM workflow for 3D reinforced concrete modeling. After the testing and development phase, proper training needs to be given to the teams including Draftsmen, Structural Engineers, Lead Engineers, and Management. Everyone in the group should be aware of the potentiality of a parametric 3D BIM model of reinforced concrete rebar can bring if it is correctly implemented.

In this phase, let the BIM expert get involved in the task force and let him work in close contact with the structural engineers and draftsmen. This would ensure smooth collaboration. For implementation, start with a small or a pilot project. The experience will show the importance of BIM and its capability to encourage collaboration between the departments. BIM will allow a faster and more reliable documentation process with higher and accurate detailing.

Would you like to share your Project Details? We would be glad to discuss it with you! Click here to send us an E-mail now!

You can also call us on – (860) 317-7105

5 Tips for Effective Implementation

The following tips have to be developed and implemented to use Revit effectively for a solid workflow. The tested methodology and so far developed customization have to be implemented to model concrete rebar reinforcement.

- Set-up Revit families, parameters and rebar shapes

- Freeze design

- Create Bending Schedules

- Quality Control Views

- Congested Nodes

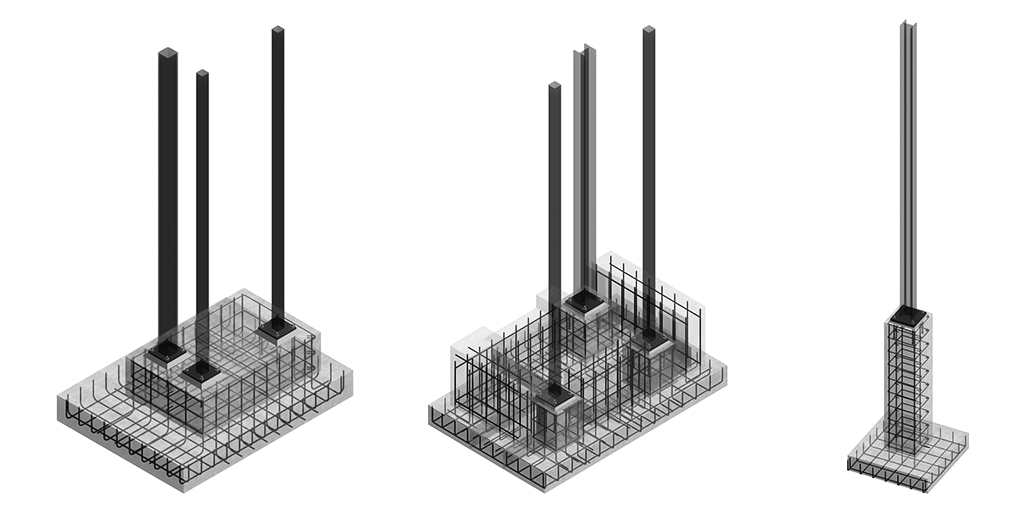

- Revit Families– It is important to define custom Revit families for all the concrete objects, anchor bolts, and insert plates. All these Revit families once made should have set parameters as they will be used to store information required to generate the Bill of Materials (BOMs) of the project.

- Parameters & Rebar Shapes– It is important to standardize the parameters and structural rebar shapes as much as possible at the beginning of the project. Every user must work with this set combination of parameters to generate data constantly, repeatedly, and can be managed easily. This will validate the design provided by the structural engineers and will calculate the steel-concrete ratio of the foundation automatically.

Once the design and drawings issued for construction have been finalized, freeze the model to avoid any unwanted changes before the next revision. For this, one can use the tools available in Revit. While placing the rebar, it is important to pin and group them and work with partitions that will uniquely identify different cages.

It is important to create and produce a bending schedule directly from the model. This ensures complete reliability between the model, documentation, and fabrication sheets. An automatic bending schedule can be created using the parameters embedded in the bars. The schedule is customizable and is parametric, and can be adapted as per the requirement of the project.

4. Quality Control View

For visualization, assign a color to each type of rebar and use it in specific 3D views to instantly visualize if everything is modeled correctly. The color should be correlated to the available parameter in each rebar called “Bar Comment. Entered values will trigger the color of the rebar and can be seen in the filters and the 3D result of the design.

It is very difficult to work with congested nodes. The structural engineers only provide the reinforcement area and undetailed sketches for the position of the main bars in the structure. It is the responsibility of the draftsmen to identify the reinforcement area and translate it into precise fabrication drawings. This becomes even more complex when we work with big structures as it is impossible to position every rebar leading to misunderstanding, possible site mistakes, waste of time and money. With the help of BIM and it’s interdisciplinary capabilities, it can handle and help to position every rebar in the structure irrespective of the scale of the project.

Would you like to share your Project Details? We would be glad to discuss it with you! Click here to send us an E-mail now!

You can also call us at – (860) 317-7105

Cost & Benefit Analysis of Reinforced Concrete Rebar Modeling

There is no mathematic equation to evaluate the Reinforced Concrete Rebar Modeling Return of Investment. But company can definitely evaluate the BIM workflow on the basis of the costs organization has to incur and to the benefit it reaps later. We have evaluated the implementation of BIM workflow on few pointers, and it does not only limit to these.

The company’s transition from the traditional way of working and implementation of BIM workflow will incur two types of costs.

- One-off cost: These are those cost that includes new hardware cost and workflow definition cost. BIM requires powerful hardware and a well-defined workflow which more investment and time.

- Repetitive cost: There are certain repetitive costs that include, hiring BIM specialists or outsourcing BIM and continuous training of the staff to get accustomed to BIM. In addition to this, one might lose some time in the process of understanding the peculiarities. With every project, the depth of understanding is going to increase.

With the involved costs, there are benefits that one can reap with the implementation of BIM and they are:

- Reliability: With this workflow, reliability increases as one structural model is to be used to produce fabrication sheets, detail drawings, analytical data for the engineers and bills of quantities, etc.

- Automatic BBS: Generation of e coherent bending schedule without having to trust any other source of documentation like an excel file, AutoCAD macros, or a subcontractor.

- Avoid Errors and Faster Updating: It ensures constructability due to fewer errors by inaccurate 2D drawings. With the power of 3D visualization, consistency increases as less RFI get generated resulting in less time spent during construction.

About the Author

Nirav Shah is a seasoned marketing leader with over 20 years of global B2B experience across the high-tech, IT, and AEC industries. He specializes in project management, digital marketing, brand positioning, and sales enablement. Until March 2024, Nirav led marketing initiatives aimed at delivering client-centric solutions while driving operational excellence. Known for his disciplined execution and ability to build and motivate high-performing teams, Nirav is a lifelong learner, dedicated to continuous improvement.